Alvier Mechatronics is an innovative engineering service provider for smart and sustainable eDrive solutions.

We offer a fast track from concept through design, simulation, prototyping and validation.

COMBINING SYSTEM, DESIGN, AND MATERIAL COMPETENCE WE OPTIMIZE YOUR eDRIVE!

OUR SPECIALIZATION /

SIMULATION DRIVEN DESIGN

YOU ARE THE ONE!

To support our growth, Alvier Mechatronics is looking for creative, brilliant talents with a keen sense of partnership and customer satisfaction.

You want to become one of us?

Check the open positions and join our team.

SUSTAINABILITY

We provide the mobility industry with engineering services to support sustainable electrified propulsion solutions across automotive, commercial vehicle, off-highway, marine and aerospace applications. Our sustainability focus: improvements in the use of CO2, resulting in an overall reduction during the development process, to complement both companies’ ability to reduce CO2 production during system operation.

Join in: Sustainability Day 2024

Join in: Sustainability Day 2024 ADVANCEMENTS IN RADIAL FLUX ELECTRIC MACHINES

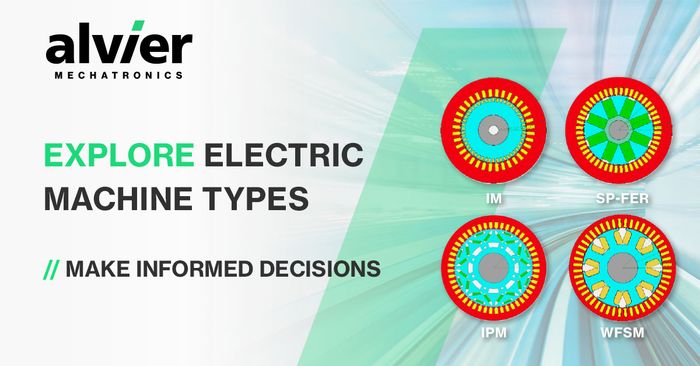

ADVANCEMENTS IN RADIAL FLUX ELECTRIC MACHINES EXPLORE ELECTRIC MACHINE TYPES

EXPLORE ELECTRIC MACHINE TYPES OPTIMIZE YOUR ELECTRIC MACHINES

OPTIMIZE YOUR ELECTRIC MACHINES